Hager's New Single Module RCBO AFDD in Action

Utilising existing feedback from over 5,000 two-module-wide units and an additional field trial with 300 single module devices, our new Arc Fault Detection Device with ProTools diagnostic software benefits from extensive field trials to guarantee best-in-class performance.

Real Life Feedback

Offering real-life feedback from these installations, we were able to modify the algorithm to accommodate new product signatures prior to market launch to provide installers with the ‘fit and forget’ reassurance they have come to expect from our products.

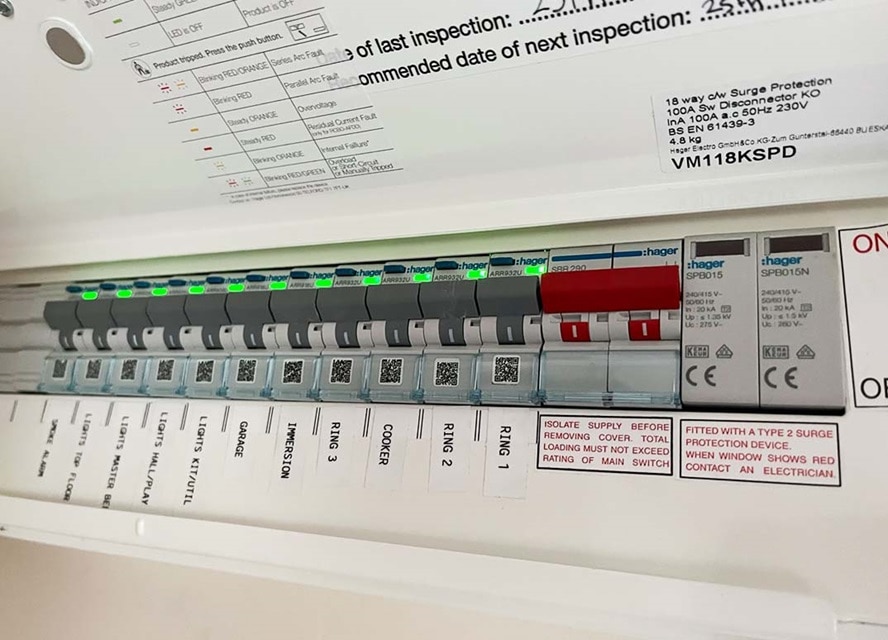

Participating in the trial, Hager’s very own Country Marketing Leader, Ian Smith, had the latest single module device installed in his home.

With the property already benefiting from a Design 30 consumer unit installation, our technical team were able to upgrade the unit to include our new single module RCBO AFDD.

Typically, Arc Fault Detection Devices would be installed on socket circuits. However, for trial purposes, Ian’s Design 30 unit was fitted with an AFDD on each circuit, consisting of five 6A, two 16A and four 32A devices, that could be monitored throughout the trial, enabling device trips to be quickly detected and identified.

Unwanted Tripping

Benefitting from our ProTools diagnostic software, the device quickly identified a fault on the 32A device controlling the circuit connected to Ian’s garage. With ProTools - Onboard Diagnostics, the device detected a Series Arc Fault, with the LED display identifying the fault via a series of red and yellow sequences on the device indicator.

Following close monitoring of the circuit, the cause for the trip was quickly identified due to its repetitive nature; the same equipment, used at the same time of day was causing the device to trip. The cause behind the tripping was identified as Ian’s plug-in EV charger.

Upon charge completion and when attempting to disconnect from the vehicle, the electrical signatures generated by the EV charger caused a trip in the AFDD. In order to analyse the signature and update the algorithm within the AFDD, a trace box was fitted to record the circuit and waveform as the fault occurred.

Updating the Software

With the trace of the circuit and waveform recorded, our technical team utilised this information in order to analyse the traces of the waveform. In doing so, this enabled the team to modify the algorithm, ensuring the AFDD was no longer susceptible to unwanted tripping when Ian’s vehicle disconnected from the charger.

After modifying the software, our technical experts attended the site and using the ProTools In-Situ Software Upgrades via the Hager Pilot app, were able to connect to the AFDD at Ian’s property using Bluetooth technology to send the updated algorithm to the device.

Following the software upgrade within the device, the unwanted tripping caused by Ian’s electric vehicle charger has since been resolved. This new algorithm has now been incorporated into the software in all our single module RCBO AFDDs and MCB AFDDs as standard to ensure that our customers have the right tools at their disposal.

Changing the Game

Ian Wassell, our Technical and Training Manager, responsible for overseeing the trial surrounding our latest AFDD comments: “The technology in our new Arc Fault Detection Device, coupled with our innovative ProTools diagnostic software will really shape the future of AFDD technology. Eliminating the need to remove or even replace the device, installers can benefit from the advanced fault finding capabilities and the ability to resolve unwanted tripping quickly.”

Commenting on his experience with the trial, Ian Smith concludes: “From an end-customer perspective, it was really reassuring to see how quickly we can react and resolve unwanted tripping for our installers and their customers. The arrival of new technologies such as an EV charger is just one example of the complex and sophisticated electrical equipment that will be introduced in the majority of homes over the next decade. Our new AFDD with ProTools is ideally placed to support our installers in shaping the electrical world of tomorrow and I strongly believe that as a company, we are really changing the game with this device.”

Project information

Building type: Residential home

Project type: Domestic

Products used: Single Mod AFDD and Design 30 consumer unit

Want to talk to our Hager team about this project?

Technical Team

WhatsApp: 07778 161000

Email: technical@hager.co.uk